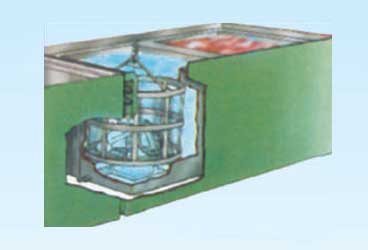

Impregnation Process

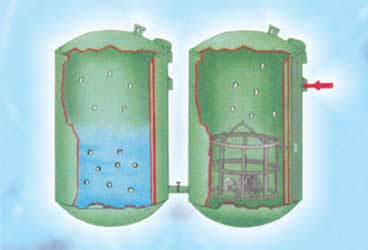

Dry Vaccum

The charge basket is lowered into the autoclave. Within the autoclave, the charge basket is subjected to high speed vacuum. Simultaneously the reservoir is subjected to similar vacuum.

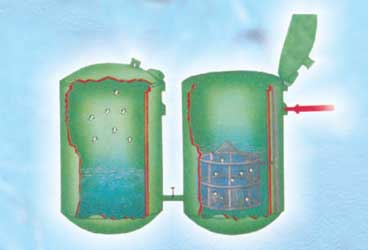

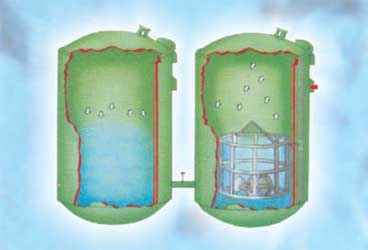

Drain

With the basket hosted over the drain station, the low viscosity sealant drains quickly and is returned to the autoclave. An automatic rotational drain station is available as an option.

Cure

Finally, the process basket is lowered into water maintained at 90 deg. C for 10 minutes allowing the sealant to polymerize. The components are now ready to use.

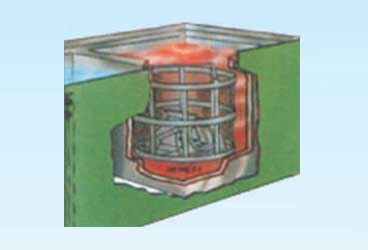

Impregnate / Wet Vacuum

The vacuum in the autoclave is maintained until the components are throughly impregnated. Then the valves is opened to return the autoclave to atmospheric pressure, further forcing the sealant into the porosity.

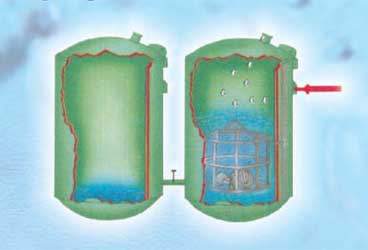

Resin Return

The autoclave lid opens and the charge basket is removed and transferred to the next station. A vacuum is generated in the reservoir and the sealant is transferred from the autoclave back into the reservoir.

Wash

The Components are washed by agitation, room temp. water, to remove residual sealant from the component surfaces.

Resin Transfer

The sealant is transferred from the reservoir to the autoclave.

Note : The whole process takes 30 minutes and the components can be used pressure tested immediately. Conditions o the Casting : Must be free from all metal swarf, rust, dirt, oil & other contaminants.